Des Hardy: Christchurch. How it all began

Roof tilers were scarce in the 1950s so I applied to the main hardware supply company and roofing firm of Ashby Bergh Ltd and did a six week tiler's journeyman course, working alongside an experienced tiler. Two weeks later I did the first roof by myself in Habgood Street, Linwood. It is still looking good today. Christchurch was on the move then with whole streets of new homes being built in all suburbs and this went on for five years or so.

Dick and I soon met and both worked on a contract basis, with each roof taking about two days to complete. This work covered battening, tiling, wiring to fastening of the tiles, ridging and pointing. Another roof was always waiting to be completed and when asked what we did for employment we would say we were “professors of tile knowledge”.

We installed many types of concrete tile including Atlas, Kaiapoi, Christchurch, Brunts, Monier, Supreme, Briscoes and Abbotsford as well as some glazed and unglazed clay tiles and decramastic, chip-coated tiles. We were the first to fix decramastic tiles in Christchurch and began to see concrete tiles being less favoured in the late 1980s as metal roofing became the vogue.

A year after installing our first roof we saw a man on a concrete tiled roof with a converted lawnmower, no blades - just roller brushes. He lowered the mower up and down over the tiles so the roof was “brushed” clean and then sprayed with copper sulphate. Job completed that same day.

That got us thinking. My wife Pam had a friend and neighbour who was an industrial chemist. He tested various chemicals and came up with a suitable product which may still be in use today. There were no problems with this product unless run-off passed into streams and waterways close to the job being sprayed; in these circumstances the run-off needed to be contained.

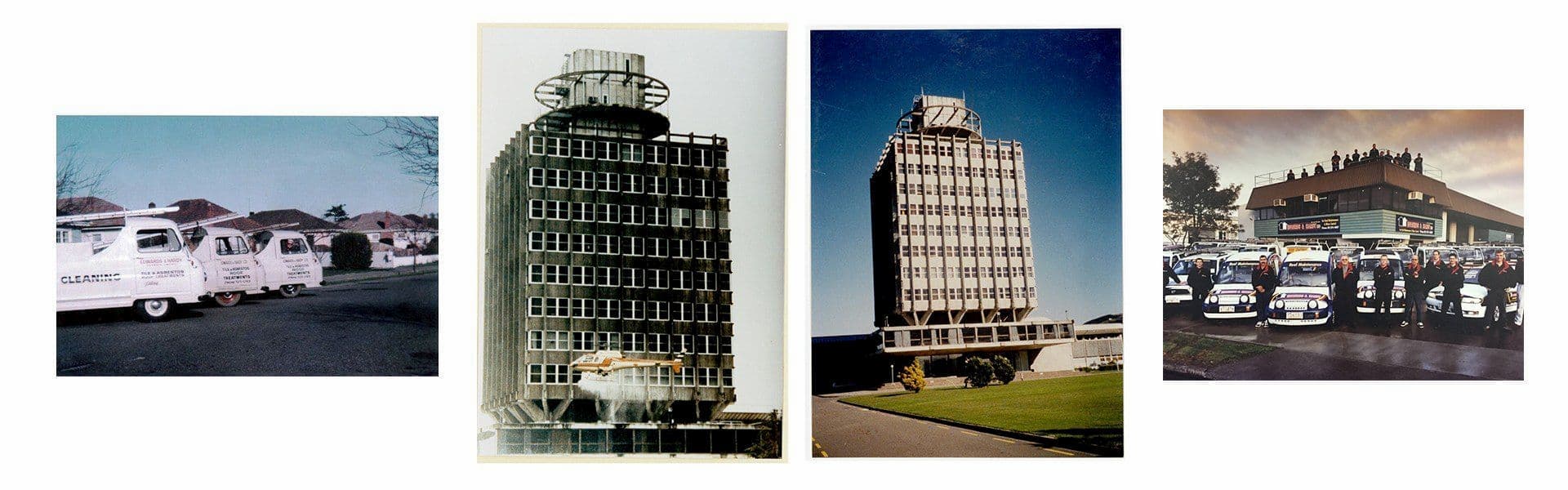

When we first started treating roofs, we would sell the service door-to-door. Dick would follow me down the street with the car and trailer which carried a large galvanised tank with all the necessary equipment to treat roofs. It came clear that to expand the workload more sales people were needed so several willing candidates were hired and trained to do what was required. Soon more treatment sprayers were required - Edwards & Hardy began to expand.

Dick took over the office and administration, also completing a management course while I retained a sales role - a combination that worked well, though I do recall one occasion when a lady told me to go away until I could present your self in a more presentable manner. We saw roof cleaning as a “must do” and we went all out to promote the cleaning of concrete and decramastic roofs. People had to get used to the idea but we knew they couldn't or shouldn't be cleaning their roof themselves.

I never missed calling just because of a rebuff - I found if I fronted up again the job would eventually come my way. Never did I miss any call to a door - I had at least a 50/50 chance of getting the job so I couldn't miss a chance with odds like that.

Over time others have made inroads to the available work in our field by cutting the price, paying no tax or GST and pocketing the money. Businesses can't cope if they have to compete with these operators. However, they don't survive if they are not well led. Edwards & Hardy was a great business venture but it had to be driven every day. Sales were the key and sales reps work according to their needs, so they require new “batteries” every day. There's always a job for a good, keen honest worker - that's what all employers require.

As work became more lucrative, Dick and I purchased an old J2 Austin Ute with metal sides, high enough so all the equipment was out of sight to the general public. We had a low-key existence: we thought the best way to keep our business to ourselves and prevent competition starting was not to advertise. It worked for us because it was eight years before anyone began to emulate our operation but they didn't know how we got the main bulk of our jobs.

In the 1980s we decided to re-coat concrete tiles and metal roofs. To prepare the surface we deployed a mobile sand-blasting machine with the help of my brother Bruce Hardy. This was ground breaking at the time - no one else had offered sand-blasting and roofs were not the only structures to be sand-blasted. Anything that couldn't be transported to Bruce's yard at Bromley, where he contracted in steel construction and sand-blasting, got this treatment.

Nothing seemed impossible for Bruce. At one stage Christchurch City Council reprimanded Edwards & Hardy following complaints about excessive dust from blasting roofs and called a halt to these activities until the dust could be reduced by at least 60%. Bruce sorted that out; he acquired a sharper sand from Birdlings Flat Beach, mixed an additive to it in a concrete mixer and the problem was solved. I never found out what the additive was except it was some form of liquid. Bruce died in 1988.

Once a roof was sand-blasted clean, which I carried out for some years, three coats of paint were applied to iron roofs - a galvanised primer and two top coats. We never had any failures that I know of - sandblasting was the answer.Tiled roofs were coated with two coats of Resene paint and in later years we developed our own product which we called “Tile Guard”.

Edwards & Hardy found it difficult to transport long ladders on trailers and hood racks so I designed fold-up ladders which could be placed on the rear seat of any car or in the boot. I purchased an Alco ladder, manufactured in Christchurch, and cut the twelve-foot ladder into three equal sections. Bruce made hinges to fold the sections, just as one would fold a builder's rule. This was ideal but I wasn't able to get a legal patent on my design because when the ladder was extended, the bottom rung wasn't the correct height off the ground. Bruce said he would solve that by making Edwards & Hardy's own complete sections so we didn't have to purchase a ladder and cut one up. The patent was then approved.

Dick decided to export ladders to the USA but that endeavour never happened; because of the US laws we would be liable for any accident that may be caused by use of the ladder. We named our ladders small or large the Mini Maxi - that as when mini skirts were the fashion of the day. I still retain the original ladder. We sold the patent to a Christchurch ladder company and the name is forgotten.

These days the laws on safety are quite stringent; rules in our day didn't seem to exist. When treating roofs, I used to fasten the spray hose around the cylinder pipe or lift a tile and tuck the hose beneath it. That gave all the safety support required - I never had an accident

I remember we were working on a glazed tile roof in Lincoln: Dick was fixing the ridge tiles on the main ridge and I was mixing the sand and cement in a bucket on the wooden terrace. It was about 10am and the lady owner came out with a tray of tea and goodies for us. I called up to Dick “cup of tea ready” then seconds later we heard a loud thump and Dick appeared, standing on the terrace holding the TV aerial in his right hand looking to me just like the Statue of Liberty. The aerial had come adrift as he slipped and grabbed it. The homeowner was aghast as Dick said: “Milk and sugar please”. He wasn't injured.

On another occasion we were installing a two-storey, decramastic roof on a large block of flats in Fendalton. Dick was about to take the underfelt roll up on a builder's platform lift. He had the roll on his shoulder, stepped onto the platform and the lift operator pulled the lever. Up went Dick to the gib board, 50cm above the fascia board. Dick called down to ask to be lowered slightly so he could step off easily. The operator pulled the lever again and wham - down came Dick, the roll still on his shoulder, down two storeys, landing with a thump at ground level - still standing with the heavy underfelt roll on his shoulder. He wasn't injured this time either.

The very next day Dick was fixing the decramastic tiles on the rear side of the same two-storey roof. I was cutting and folding the valley tiles on the ground for Dick to set in place. The day was cold and damp and we wore parka jackets. I was around the end of the building when I heard a stressed voice calling Help, help. I rushed around to where the ladder was, looked up two storeys and saw Dick hanging upside down at the bottom of the valley. He had tripped and caught his rain jacket between his legs as he went over the spouting. He was lucky that the plumber had left the sharp right-angle joint in the spouting. Not cut off, that joint caught on Dick's jacket and saved him from serious injury. I was able to rush up the ladder, lift him back up onto the roof and help him down. In the first few days of our partnership we were working on a concrete tile roof and had an altercation over a string piece. Dick was taught to set the first batten from the fascia by using a string line, then to place a guide nail into each rafter to set the tile battens up the roof for correct spacing to the main ridge.

The way I was taught to set out the battens was to use a marker batten which I placed against the fascia edge, then placed set out nails up each rafter to the ridge.

The result was the same but Dick said it's to be done the way he had been taught and that's it. Then he told me any future differences must be talked over and resolved. In that way we will and can be good mates.

Dick and I always tried to beat each other at doing any work. It was quite fun. When ridging and pointing a roof, Dick would work on one side of the roof and I on the other. I couldn't see him, then I saw his hat move near the apex while I was only halfway up the side I was working on. This was one of Dick's jokes that he would place his hat so I would think he was beating me to the top. When I got there, he was down on the ground having a smoke.

Dick and I got on really well - I could not have teamed up with a better business partner. He was the greatest. Edwards & Hardy (Christchurch) Ltd was purchased by Gordon Thomas-Long, John Browning and Martin Hadfield in April 1997

Dick Edwards passed away in October 2004 and is buried in Akaroa Cemetery.